Maintaining your 4WD tractor's front axle is crucial for operational efficiency and longevity. This guide explores the key components, troubleshooting techniques, and part sourcing strategies for Ford/New Holland and Deutz axles, highlighting similarities and differences to help you maintain peak performance. For additional parts resources, check out this helpful website.

Decoding Your 4WD Tractor Front Axle: Key Components and Functions

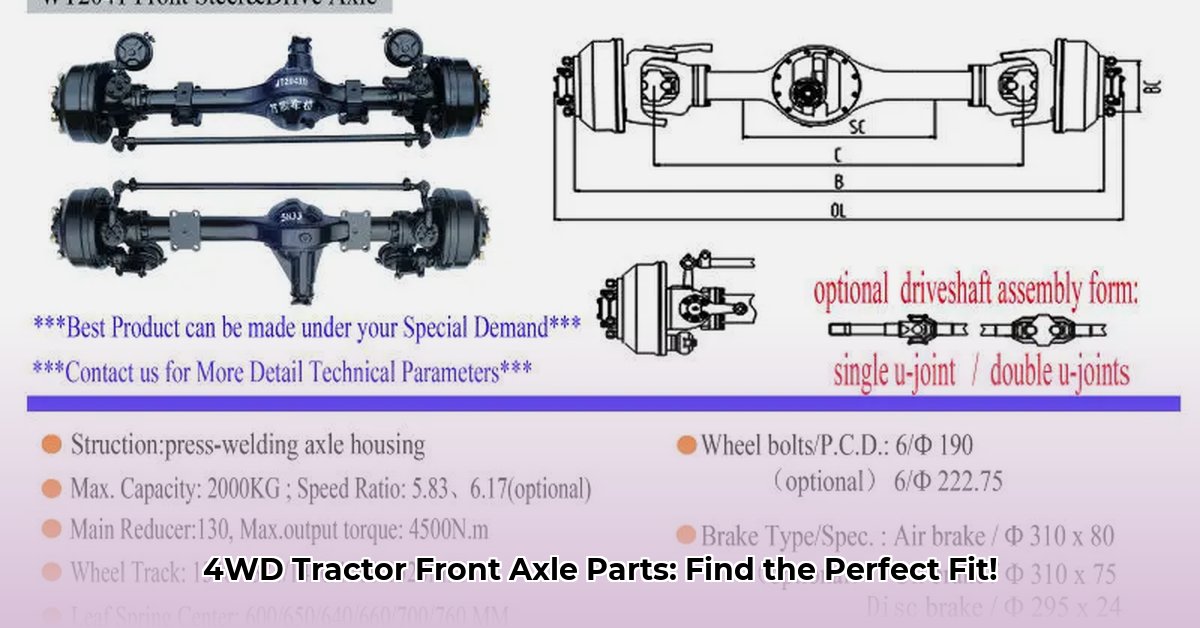

The front axle of your 4WD tractor is a complex system responsible for steering and power transmission. Understanding its components is crucial for effective maintenance and repair. Key components include:

Planetary Hub Gears: (Gears that transfer power from the axle to the wheels) These gears are vital for power transfer to the wheels. Failure can result in complete loss of front-wheel drive.

Tie Rod Ends: (Connectors that link steering components) These control steering responsiveness. Worn tie rod ends lead to imprecise steering and potential safety hazards.

Pivot Bushings: (Bearings that allow for axle articulation) These bushings ensure smooth axle movement. Wear can lead to stiff steering and premature axle wear.

U-Joints: (Joints that connect rotating shafts) These joints facilitate power transfer. Worn U-joints create vibrations and power loss.

Swivel Housings: (Components that allow wheel articulation) These housings enable the wheels to turn. Damage to these can lead to significant axle damage.

Ignoring these components can lead to costly repairs and downtime. Regular inspection and maintenance are vital.

Ford/New Holland vs. Deutz: A Comparative Overview

While both Ford/New Holland and Deutz produce robust 4WD tractors, differences exist in their axle designs and part availability. Initial research suggests that Deutz parts may be more readily available in some regions. However, further investigation is required to draw definitive conclusions about overall part availability and long-term durability. The optimal approach is to thoroughly research and compare parts before purchasing. This applies to both new and replacement components.

Component-Specific Analysis: Identifying Failure Points and Mitigation Strategies

Let's delve into the specific failure points and mitigation strategies for each key component:

1. Planetary Hub Gears: Listen for unusual noises (grinding, whining) indicative of wear. Regular lubrication with the recommended grease is crucial. Timely replacement is essential to prevent catastrophic failure, resulting in complete loss of front-wheel drive.

2. Tie Rod Ends: Regularly check for looseness or excessive play in the steering. A wobbly steering wheel is a clear sign of worn tie rod ends. Replace worn components to ensure safe and precise steering and prevent accidents.

3. Pivot Bushings: Monitor for stiffness in the steering or unusual noises while turning. Regular lubrication can extend their lifespan. Replacing worn bushings ensures smooth steering and prevents premature axle wear.

4. U-Joints: Inspect for excessive play or unusual noises (clicking or knocking). Regular lubrication is vital. Replacing faulty U-joints prevents vibration and power loss.

5. Swivel Housings: Inspect for cracks or other signs of damage. These components are critical for wheel articulation; any damage necessitates immediate repair to avoid serious accidents.

Preventative Maintenance and Troubleshooting: A Practical Guide

Proactive maintenance extends the lifespan of your front axle. Follow these steps:

Regular Lubrication: Adhere strictly to the manufacturer's lubrication schedule, using the recommended grease type. This reduces friction and extends component lifespan.

Visual Inspections: Conduct regular visual inspections of all components, checking for wear, damage, leaks, or unusual noises. Early detection prevents small problems from escalating into larger, costlier repairs.

Prompt Replacements: Replace worn or damaged components immediately. Delaying replacements can lead to cascading failures, resulting in more extensive and expensive repairs.

Part Sourcing and Selection: Choosing the Right Suppliers

Finding high-quality, correct parts is crucial. Utilize reputable suppliers specializing in agricultural machinery parts. Verify part numbers and specifications against your tractor's manual. Prioritize high-quality parts despite possible higher initial costs. The long-term cost savings associated with reduced downtime far outweigh any small initial price increase.

Risk Assessment Matrix: Potential Consequences of Component Failure

| Component | Failure Risk | Consequences of Failure | Mitigation Strategies |

|---|---|---|---|

| Planetary Hub Gears | High | Complete loss of front-wheel drive | Regular lubrication, inspection, timely replacement |

| Tie Rod Ends | Medium | Unsafe steering, accidents | Regular inspection, replacement as needed |

| Pivot Bushings | Medium | Stiff steering, premature axle wear | Regular lubrication, replacement as needed |

| U-Joints | Medium | Vibration, power loss | Regular inspection and lubrication, timely replacement |

| Swivel Housings | Low | Potential axle failure, significant repair costs | Regular visual inspection, immediate repair if damaged |

This matrix provides a general guide; consult your owner's manual for specific recommendations.

Conclusion: Ensuring Operational Efficiency and Longevity

Regular maintenance, proper part selection, and timely repairs are essential for maximizing the lifespan and efficiency of your 4WD tractor's front axle. Remember, a well-maintained tractor translates to greater productivity and reduced downtime. Investing in preventative maintenance is an investment in your farm's success.